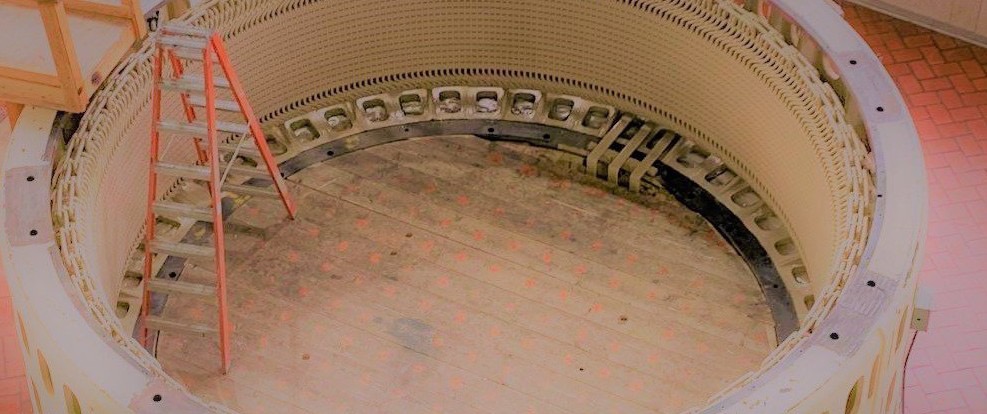

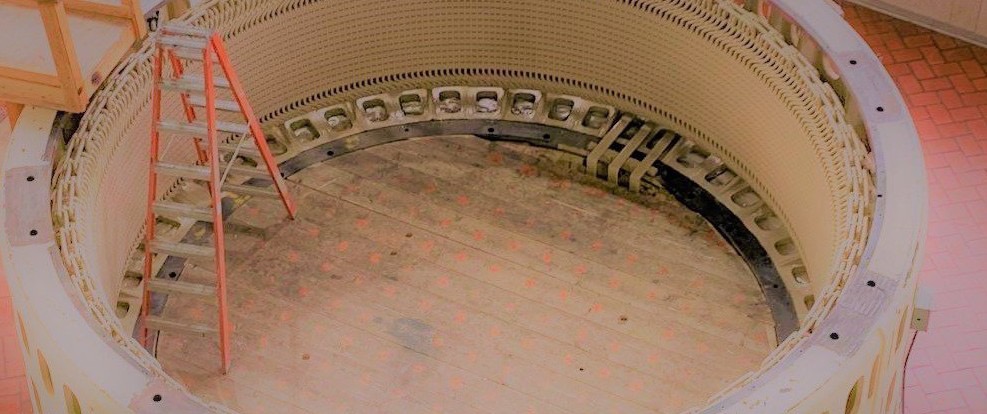

As the President and CEO of Sidewinders LLC, we are proud to announce that our newly upgraded Motor Services shop has met the criteria to be an EASA accredited service center. In addition to meeting EASA’s standards for safety, quality, and professionalism, we have acquired new equipment and tooling to increase our ability to serve a wider range of customer needs.

We sincerely thank our amazing motor shop team for their intense focus and effort toward achieving this goal! Our skilled technicians are better situated than ever to service your AC and DC motors, traction motors, rotor pole pieces, pumps, gearboxes, and more.

Thank you, EASA, for the recognition!

Glen Peterkin, President

Jan Peterkin, CEO