EQUIPMENT CURRENTLY IN USE

DYNAMIC BALANCER BY DYNA-BAL

- Weight Capacity = 10-15,000 lbs.

- Overload Weight = 15,000 lbs.

- Bearing Centers = 10 feet – 7 feet

- Maximum Swing = 8”

- Journal Diameters = 0.75” – 12”

- Drive Motor = 15 HP

CORE LOSS TESTER BY PHENIX TECH

- Core loss for motors up to 500 HP

(We can perform a traditional core ring test for largermotors/generators.)

DIP TANK

- Tank Dimensions = 5’5″ h x 5’5″ w x 5′ d

- Varnish – EB 920

BAKE OVEN BY STEELMAN

- Internal Dimensions = 6’ h x 6’ w x 8’ d

- Internal Volume = 288 feet

- Maximum Temperature = 500° F

BURN-OFF OVEN

BY POLLUTION CONTROL PRODUCTS

BY POLLUTION CONTROL PRODUCTS

- Working Chamber Dimensions = 7’9” h x 6’6” w x 9’9” d

CRANE

- 25 – ton lifting capacity

VPI SYSTEM BY Heattek, INC.

- Vessel dimensions = 5′ diameter and 6′ internal depth

- Resin – CC 1305

- Automated Process

VERTICAL PRESS BY POWER TEAM

- 3 HP pump

- Up to 400 tons

TEST BOARD BY JENKINS ELECTRONICS

- Dynamicaly Tests motors up to: 4200 VAC at 69 AAC Max Capacity

- 600 VAC, 480 AAC

- 2400 VAC, 120 AAC

- 4200 VAC, 69 AAC

- DC Field Output = 0 – 500 VDC; 300 ADC

- 500 KVA AC/DC MV Test System

AUTOMATIC COIL-WINDER BY SAMATIC

- Bi-directional AC and DC winding

- Pulling power = Up to equivalent of 20 AWG 12 in parallel

- Max peak-to-peak coil size = 4′ 2.5″

Radial Drill Press

- Table size of 25’ x 51’

- stroke 24” and arm 4’9”

- 3 HP

- 220v/ 3 phase

- Dimensions 46” W x 113” L x 98” H

Boring Mill

- 20 HP

- Voltage 220 / 3 phase

- RPM: 22 to 1600

- Dimensions: 78” x 184” 140”

EQUIPMENT TO BE INSTALLED SOON

BAKE OVEN BY STEELMAN

- Working chamber dimensions = 12’ h x 12’ w x 12’ d

- Internal volume = 1,728 feet

- Maximum temperature = 500° F

BURN-OFF OVEN (AUTOMATIC) BY STEELMAN

- Anticipated installation date: TBD

- Working chamber dimensions = 12’ h x 12’ w x 12’ d

- Internal volume = 1,728 feet

Vertical Lathe

- HP 40

- Voltage 440 / 3 phase

- Dimensions: 188” x 154” x 132”

OFFSITE RESOURCES

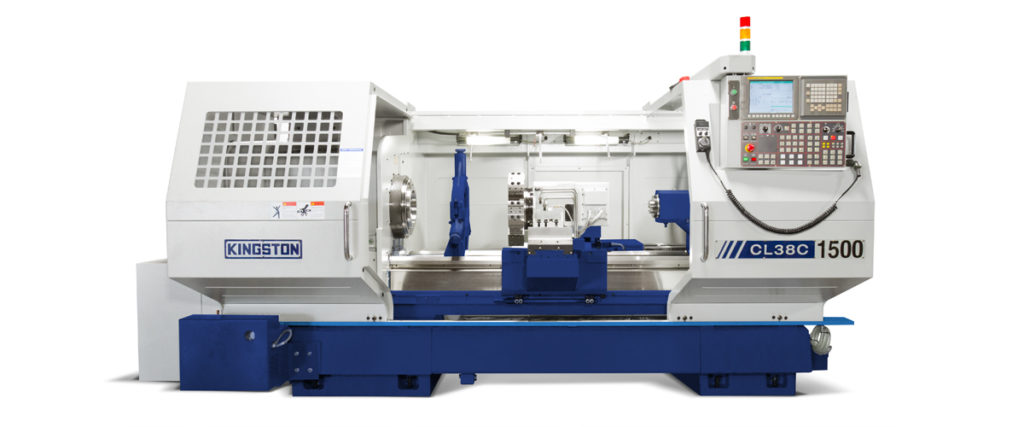

LATHES

- Dianichi; 3’5″ swing; 20′ centers

- Lion; 2’4″ swing; 10′ centers

- Summit; 20″ swing; 7′ 8″ centers

- Kingston; 22″ swing; 7′ 8″ centers

- Kingston; 22″ swing; 10″ centers

- Kingston; 26″ swing; 10″ centers

- Victor; Toolroom; 17″ swing; 5′ centers

KNEE MILLS

- Four 10″ x 4’6″ knee mills

HORIZONTAL BORING MILL

- G & L 3” Bar

- G & L 4” Bar

- Gray floor mill

BALANCER

- Schenck; 4′ swing; capacity = 1,500 lbs and 7′

GRINDER

- No change to first bullert

- Landis OD; 6″ swing; 18′ centers

VERTICAL BORING MACHINE

- Bullard, 5′ 10″ swing; 4′ under rail

- Bullard, 5′ swing; 3′ 4″ under rail

- Bullard, 6′ 8″ swing; 5′ under rail

- Bullard, 10′ swing; 7′ 8″‘ under rail

LAPPING MACHINES

- Spitfire two; 3′ machines

COMPUTER NUMERIC CONTROL TOOLS

- Millport; 3axis; 30″ x 15″ x 16″

- Fadal VMC; 40″ x 20″

- Proto TRAK lathe; 16′ x 30″

- Proto TRAK lathe; 18′ x 40″

- Plasma cutting table; 5′ x 10′; 1″ plate capacity

For assistance, please contact:

ERIN PUGMIRE

Motor Services Office Manager

M: 385.900.9266 | O: 801-250-6267

[email protected]

MARTIN DOONEY

Motor Services Manager

M: 385.900.9070 | O: 801.250.6267 ext. 2809

[email protected]